Hometown Flavors: Aoki Shoten’s Ita-wakame Sheets

Ita-wakame are dried wakame seaweed sheets and are one of the most popular souvenirs from Daisen. When I first saw Ita-wakame, I was surprised and wondered why wakame were shaped in such a way.

Ita-wakame comes in two different sizes.

“Aoki Shoten (store)” is in Nawa, which is in the central part of Daisen Town, and is one of the most famous Ita-wakame producers in Tottori Prefecture. I visited Aoki Shoten, which has long been loved by the locals.

I arrived a little after 9:00am, and already, there were several sheets of wakame placed in a dryer. According to the staff, they started work at 4:00 in the morning. “The wakame season is limited, so during the peak season, we work very intensively from 4:00 to 7:00 every morning without rest.” said the founder and the owner of Aoki Shoten, Tsuruichi Aoki (aged 80).

Tsuruichi left Mikuriya at the age of 18 to work in Osaka; however, when he was 23, he hurt himself in a factory machine accident and was unable to continue his work there. It was then that he decided to return to his hometown, Mikuriya, and start wakame production. First, he produced ordinary wakame like ones we often see at stores, but at the age of 26, he began Ita-wakame production by learning from his friend. “San-in Region’s weather makes it difficult to dry wakame if they lie on top of each other.” Tsuruichi says.

In fact, San-in Region is famous for its high humidity and few sunny days compared to other areas in Japan. Today’s modern tools and equipment such as dryers help them not rely on the weather. However in the past, they had a lot of difficulties as they had to dry wakame on the roof or in the yard. These wakame sheets are a result of San-in people’s innovative ideas.

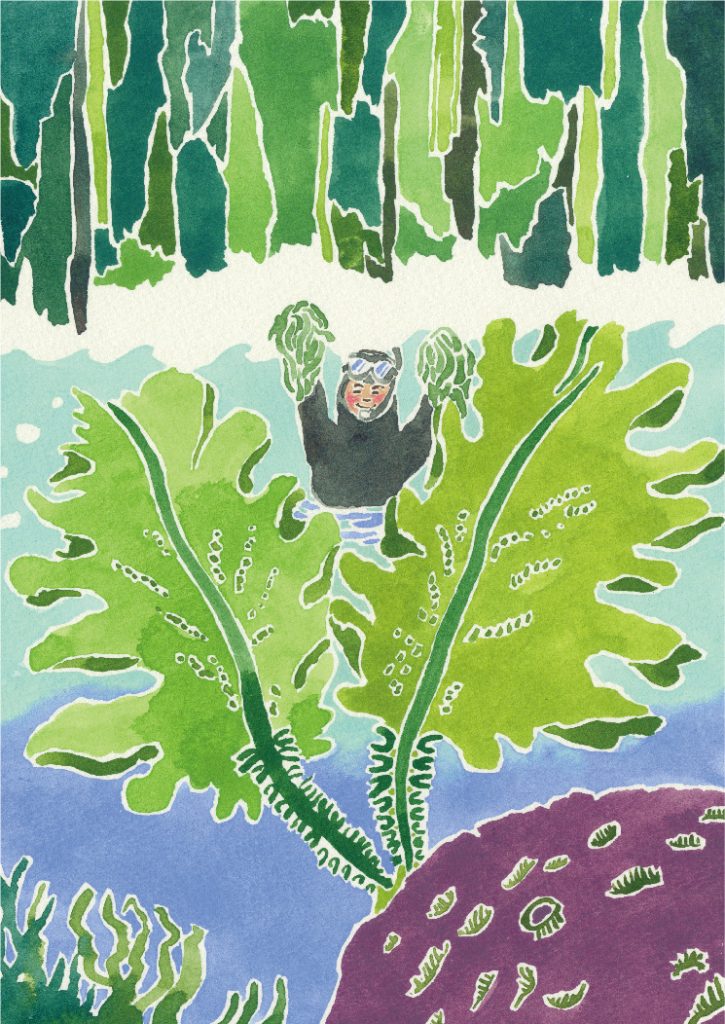

Tsuruichi Aoki, a gentle owner with a kind smile.

First Tsuruichi washed fresh wakame with water. That’s the most important process. “I make adjustments and change the duration of washing according to the salinity and softness of wakame. If I wash wakame for too long, it loses not only its salinity but also its umami flavor.”

When I told Tsuruichi how I didn’t understand what he meant by making adjustments, he laughed and said, “If you keep on doing it, you get it.”

Suddenly, we heard Tsuruichi’s wife calling out, “Oto-san (father), the wakame over there is ready for processing! Don’t forget!” Tsuruichi’s face flinched as he remembered what he had to do. He quickly carried the wakame and responded, “All right, I’ll do that…”

The staff in the room laughed aloud watching the couple’s exchange of words. I also couldn’t help myself from laughing.

The members working at this energetic factory are Tsuruichi’s family and some part-time workers. On the day of my visit, there were Tsuruichi, his wife, two daughters, a relative and a lady who had been producing Ita-wakame for many years. Usually Tsuruichi’s son, who was away on business that day, also works there and supports the family business.

The wakame washed by Tsuruichi was given to the ladies. They then placed pieces of wakame on a net and created one big sheet. This process is also difficult but important. If you spend too much time doing it, the color of wakame changes or they stick to each other. Every one swiftly placed wakame on the net checking its size, thickness and shape.

“It looks like patchwork” I said.

“Yes, but it’s more like a jigsaw puzzle because we fill in the pieces missing.” Tsuruichi’s older daughter answered as she laughed.

The wakame sheets are dried for 4 hours. When they are dried, they become vivid green. Once the dryer is open, the aroma of the sea fills the room.

Wakame is quickly placed on the net. They do this as they visualize the completed sheet.

“What is the greatest thing about this job?” I asked Tsuruichi.

He instantly answered, “The fact that I can work together with my family. We often argue, but we soon make up because we are a family”

His family members looked happy listening to his comments. When I was interviewing Tsuruichi’s wife on the early hard years, how she felt when Tsuruichi started making wakame and other old memories, Tsuruichi was listening in from a distance with a smile. I could see that this delicious Ita-wakame was the fruit of their teamwork, trust and love.

It was really a fun workplace. “We need to make a good atmosphere and have fun because it is hard to work on cold winter mornings before dawn.”

With love and care, Aoki-san and his team make this special Ita-wakame using the mineral-rich Daisen water which runs through Nawa River into the Sea of Japan. Why not take home one as a souvenir from Daisen?

【Here you can buy】